Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: BHC

Place Of Origin: China

Plastic Molding Process Type: Injection

Processing Service: Moulding

Surface Finished: IML/IMD,Texture, Polish

Mould Material: NAK80, S136,2316,2738, H13,718H

Products Material: ABS, PC, POM, PA, PVC, PP, PE, PC+ABS, PMMA

Injection Machine: 100Ton, 260Ton,350Ton, 450Ton, 550Ton,800Ton

Mould Cavity: Single, Multi or as per request

Packaging: Exported standard carton

Productivity: 50 K/month

Transportation: Ocean,Land,Air,Express,Express

Place of Origin: Dongguan China

Supply Ability: 50 K/month

Certificate: ISO9001,ISO14001

HS Code: 3926909090

Port: Shenzhen,Hongkong

Payment Type: T/T,Paypal

Incoterm: FOB,EXW,DDP,DDU,Express Delivery

We produce: Mold, Prototyping, injection molding, CNC Machining, product assembly, surface printing, spraying the surface integration

Pls provide: 2D, 3D, samples, or the size of the multi-angle pictures

Mould Time:20-35 Days

Product time: 7-15 Days

Moud precision: +/-0.01mm

Mould life: 50-100 million shots

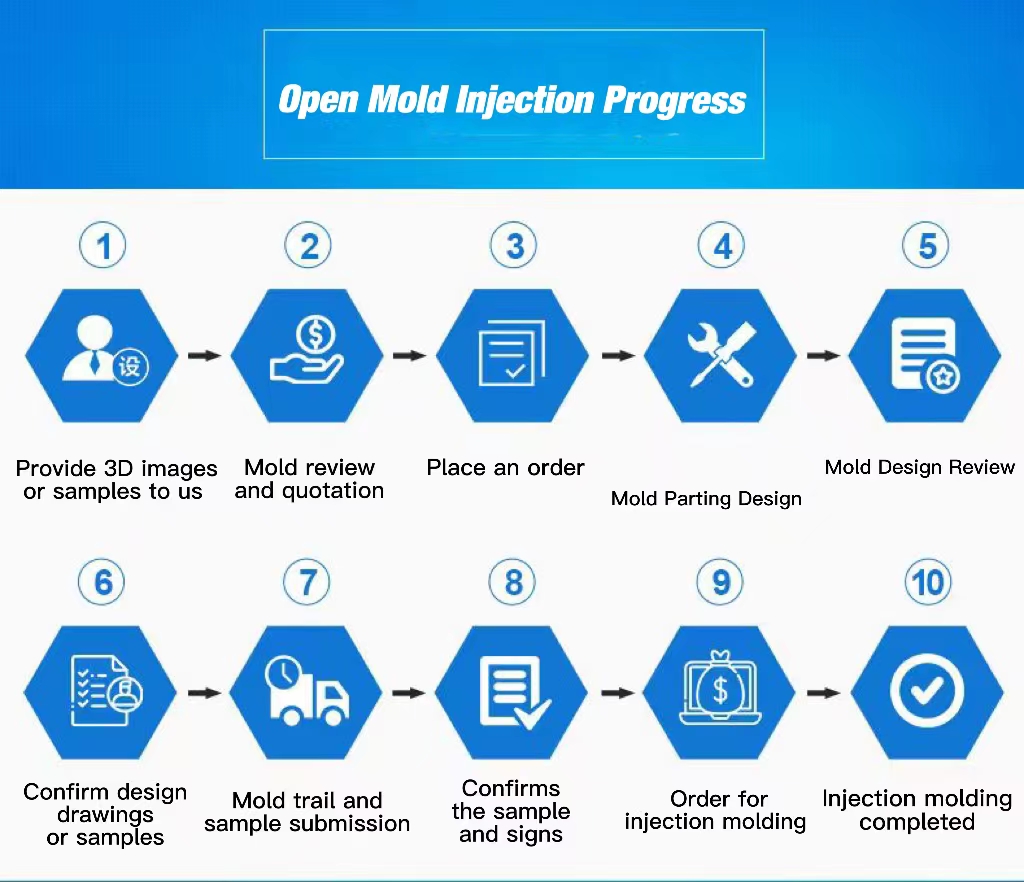

Producing Process: Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process- complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples

Mould cavity: One cavity, multi-cavity or same different products be made together

Mould material: 2738,2344,718,S136,8407,NAK80,SKD61,H13

Runner system: Hot runner and cold runner

Base material: 2738,2344,718,S136,8407,NAK80,SKD61,H13

Finish: mirror finish, matte surface, printing

Standard: HASCO, DME or dependent upon

Main thechnology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Software: CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

Product material: ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

Quality system: ISO9001:2015

Establish time: 30days

Equipment: CNC,EDM,Cutting off Machine,plastic machinery,etc plastic suitcasemould

Product Categories : Plastic Injection Mould > Insert Plastic Injection Mould

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.