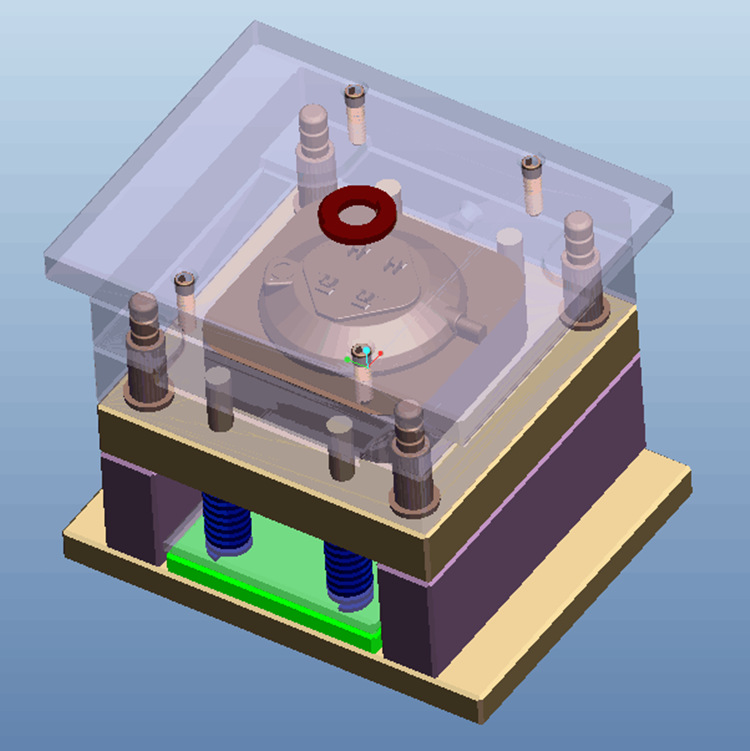

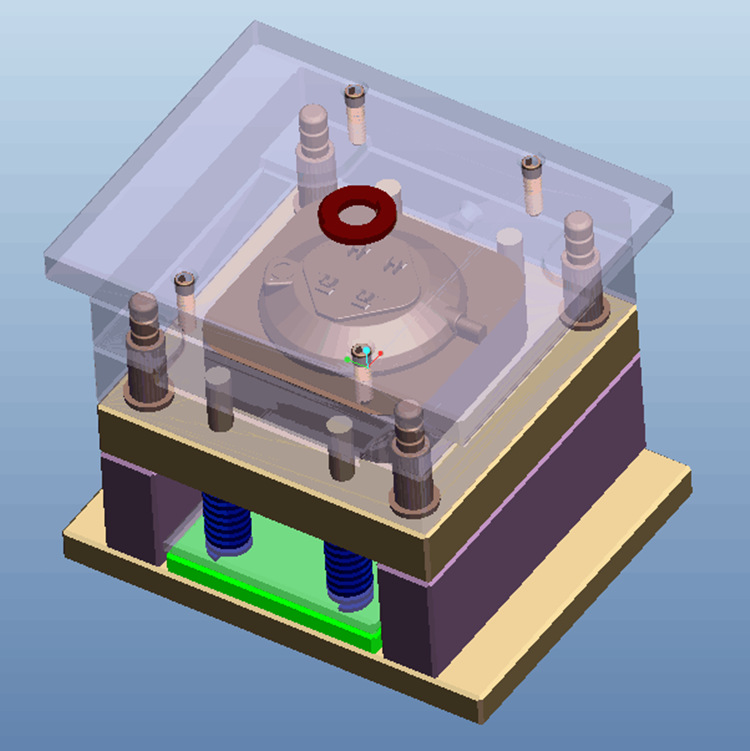

Injection mold design is a very important part of modern life, the application of many tools in people's lives, a lot of electronic mechanical equipment, are inseparable from injection mold design, it is precisely because of this, the market development of injection mold design has been very good. Injection mold design is an important process equipment for the production of various industrial products, with the rapid development of injection mold design industry and the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial sectors, the product requirements for molds are getting higher and higher, and the traditional plastic mold design method has been unable to meet the requirements of product replacement and improvement of quality. The plastic is heated and melted in the heating barrel at the bottom of the injection machine, and then pushed by the screw or plunger of the injection machine, through the injection machine nozzle and the pouring system of the mold into the mold cavity, the plastic is cooled and hardened, and the product is obtained by demoulding. Its structure is usually composed of forming parts, pouring system, guiding parts, pushing mechanism, temperature control system, exhaust system, support parts and other parts. The manufacturing material is usually plastic mold. Injection molding processing method is usually only suitable for the production of hot plastic products, the plastic products produced by injection molding process are very extensive, not only in the plastic daily necessities mold production products, from daily necessities to all kinds of complex machinery, electrical appliances, transportation parts, etc., are molded with injection molds. It is a very widely used processing method in the production of plastic products.

Injection mold design is an important process equipment for the production of various industrial products, with the rapid development of injection mold design industry and the promotion and application of plastic products in aviation, aerospace, electronics, machinery, ships and automobiles and other industrial sectors, the product requirements for molds are getting higher and higher, and the traditional plastic mold design method has been unable to meet the requirements of product replacement and improvement of quality. The plastic is heated and melted in the heating barrel at the bottom of the injection machine, and then pushed by the screw or plunger of the injection machine, through the injection machine nozzle and the pouring system of the mold into the mold cavity, the plastic is cooled and hardened, and the product is obtained by demoulding. Its structure is usually composed of forming parts, pouring system, guiding parts, pushing mechanism, temperature control system, exhaust system, support parts and other parts. The manufacturing material is usually plastic mold. Injection molding processing method is usually only suitable for the production of hot plastic products, the plastic products produced by injection molding process are very extensive, not only in the plastic daily necessities mold production products, from daily necessities to all kinds of complex machinery, electrical appliances, transportation parts, etc., are molded with injection molds. It is a very widely used processing method in the production of plastic products.  Injection mold plays a very important role in people's lives, and many of the tools used in people's lives are produced by injection mold processing; Injection mold is a special tool for the production of plastic products, and it is also a tool that can help the structure of plastic products be more complete and the size is more accurate.

Injection mold plays a very important role in people's lives, and many of the tools used in people's lives are produced by injection mold processing; Injection mold is a special tool for the production of plastic products, and it is also a tool that can help the structure of plastic products be more complete and the size is more accurate. In a lot of platforms, we will see the figure of injection mold, and with the rapid development of the plastic industry and the increasing application platform of plastic products, so now the standard for injection mold production is also improving, and the traditional mold making process is no longer applicable to the current industry.

Welcome to customize: Plastic Injection Mould, IMD Technology, Plastic Injection parts, Silicone Rubber Mould, Prototyping.